Designing Tomorrow: Energy Container Development 2024 Latest

Commercial and industrial sectors have long recognized the importance of energy storage systems (ESS) in managing their energy needs efficiently. These systems play a vital role in stabilizing energy supply, reducing costs, and enhancing grid reliability. In this article, we delve into the significance of ESS in commercial and industrial settings, explore various energy storage technologies, and highlight the pivotal role of energy containers within these systems.

Introduction: Understanding Commercial and Industrial Energy Storage Systems (ESS)

1.1 Definition and Importance of ESS in Commercial and Industrial Settings

Defining ESS: Commercial and industrial energy storage systems refer to technologies that store electrical energy for later use. They are crucial for managing peak demand, integrating renewable energy sources, and ensuring uninterrupted power supply.

Importance in the Industry: ESS in commercial and industrial settings offers numerous benefits, including demand charge reduction, grid stabilization, backup power during outages, and facilitating renewable energy integration.

1.2 Overview of Different Types of Energy Storage Technologies

Battery Storage: Lithium-ion, lead-acid, and flow batteries are commonly used in commercial and industrial ESS due to their high energy density and fast response times.

Mechanical Storage: Technologies like flywheels and compressed air energy storage (CAES) utilize mechanical mechanisms to store and release energy.

Chemical Storage: Hydrogen storage systems store energy in the form of hydrogen gas, offering long-duration storage capabilities.

Significance of Energy Containers in ESS

Energy containers play a crucial role in housing and protecting energy storage systems, particularly in commercial and industrial applications. Here, we explore the types of energy containers used in these settings and their respective advantages and disadvantages.

2.1 Types of Energy Containers for Commercial and Industrial ESS

Containerized ESS: These systems are housed within shipping containers, providing mobility, scalability, and ease of deployment.

Non-Containerized ESS: Non-containerized systems are built on-site without the use of standardized containers, offering more flexibility in design but requiring dedicated infrastructure.

2.2 Overview of Various Energy Container Designs and Materials

Standardized Containers: Utilizing shipping containers as energy containers offers standardized dimensions, allowing for easy transportation and installation.

Custom-built Containers: Some manufacturers, like CNTE, offer custom-built energy containers tailored to specific project requirements, optimizing space utilization and performance.

2.3 Advantages and Disadvantages of Different Container Types

Containerized ESS: Advantages include rapid deployment, modular scalability, and enhanced security. However, limitations may arise concerning limited space for system components and potential constraints on system customization.

Non-Containerized ESS: These systems offer greater flexibility in design and configuration, allowing for optimized use of available space. However, they may require more extensive site preparation and lack the mobility of containerized systems.

Key Features and Components of Energy Containers

Energy containers house essential components and systems crucial for the operation and safety of ESS in commercial and industrial settings. Understanding these components is vital for ensuring efficient and reliable energy storage solutions.

3.1 Detailed Breakdown of Essential Components in an Energy Container

Battery Banks: These comprise the primary energy storage medium, typically consisting of arrays of batteries configured to meet specific energy storage requirements.

Inverters and Power Electronics: Convert stored DC energy into AC power for use in commercial and industrial applications.

Temperature Management Systems: Ensure optimal operating conditions for batteries, mitigating thermal runaway risks and extending battery lifespan.

3.2 Importance of Safety Features in Commercial and Industrial Applications

Fire Suppression Systems: Energy containers are equipped with fire suppression mechanisms to mitigate fire risks associated with battery operation.

Emergency Shutdown Systems: Enable rapid isolation of the energy storage system in case of emergencies, safeguarding personnel and property.

3.3 Role of Monitoring and Control Systems Within the Container

Battery Management Systems (BMS): Monitor and manage battery performance, ensuring optimal charging, discharging, and overall system health.

Remote Monitoring: Allows for real-time monitoring of system performance, enabling proactive maintenance and troubleshooting.

Design Considerations for Energy Containers in Commercial and Industrial ESS

When designing energy containers for commercial and industrial energy storage systems (ESS), several crucial factors must be considered. These considerations ensure optimal performance, integration with existing infrastructure, and compliance with regulations.

4.1 Factors Influencing Container Design

Space: Maximizing space utilization within the container while accommodating all necessary components is paramount. This involves careful layout planning and selection of compact yet efficient equipment.

Scalability: Containers should be designed to accommodate future expansions or modifications to the energy storage system. Modular designs allow for seamless integration of additional storage capacity or upgraded technology.

Integration with Existing Infrastructure: Compatibility with existing electrical and mechanical systems is essential for smooth deployment and operation. Customization may be required to ensure seamless integration with the surrounding infrastructure.

4.2 Environmental Considerations and Regulations

Environmental Impact: Energy containers should be designed with sustainability in mind, utilizing eco-friendly materials and minimizing energy consumption during operation. Compliance with environmental regulations ensures responsible deployment and operation of ESS.

Safety Regulations: Adherence to safety standards and regulations is crucial to mitigate risks associated with energy storage systems. This includes considerations for fire safety, structural integrity, and hazardous material handling.

4.3 Case Studies Showcasing Innovative Container Designs

Case studies highlighting innovative container designs provide valuable insights into the practical application of design considerations. Manufacturers like CNTE have demonstrated creativity and ingenuity in developing energy containers tailored to specific project requirements. From compact modular designs to custom-built solutions, these case studies showcase the versatility and effectiveness of energy containers in diverse commercial and industrial settings.

Installation and Maintenance of Energy Containers

Efficient installation and regular maintenance are essential for ensuring the reliability and longevity of energy containers in commercial and industrial ESS. Following best practices and implementing effective strategies minimize downtime and maximize system efficiency.

5.1 Best Practices for Installing Energy Containers

Site Preparation: Adequate site preparation is crucial to ensure a stable foundation for the energy container. This includes leveling the ground, providing proper drainage, and ensuring accessibility for transportation and installation.

Electrical and Mechanical Integration: Close coordination with electrical and mechanical contractors is necessary to seamlessly integrate the container with existing infrastructure. Proper wiring, ventilation, and cooling systems must be installed to ensure safe and efficient operation.

5.2 Importance of Regular Maintenance and Monitoring

Scheduled Inspections: Regular inspections of the container and its components help identify potential issues early and prevent costly downtime. This includes checking for signs of corrosion, loose connections, and abnormal battery performance.

Remote Monitoring Systems: Implementing remote monitoring systems allows for real-time monitoring of system performance and early detection of anomalies. This enables proactive maintenance and troubleshooting, minimizing the risk of unexpected failures.

5.3 Strategies for Minimizing Downtime and Maximizing Efficiency

Predictive Maintenance: Utilizing predictive maintenance techniques, such as data analytics and condition monitoring, helps anticipate maintenance needs and schedule downtime proactively. This minimizes disruptions to operations and maximizes system uptime.

Backup Systems: Incorporating backup power sources or redundant components mitigates the impact of potential failures, ensuring continuous operation even during maintenance activities or unexpected events.

Future Trends and Innovations in Energy Container Technology

As the demand for energy storage solutions continues to grow, advancements in energy container technology are poised to drive innovation and reshape the commercial and industrial sectors.

6.1 Emerging Technologies Shaping the Future of Energy Containers

Advanced Materials: Continued research and development in materials science enable the use of lightweight, durable materials that enhance container performance and longevity.

Smart Integration: Integration of smart technologies, such as IoT sensors and artificial intelligence, enhances monitoring, control, and optimization of energy containers, improving overall system efficiency and reliability.

6.2 Potential Advancements in Container Design and Efficiency

Compact Designs: Further optimization of container layouts and component placement maximizes space utilization and allows for greater storage capacity within a smaller footprint.

Energy Efficiency: Focus on energy-efficient components and systems reduces energy consumption and operational costs, making energy storage solutions more economically viable.

6.3 Implications of Energy Storage Trends on Commercial and Industrial Sectors

Grid Resilience: Energy storage solutions bolster grid resilience, providing backup power during outages and reducing strain on the electrical grid during peak demand periods.

Renewable Energy Integration: Energy containers facilitate the integration of renewable energy sources, enabling greater reliance on clean, sustainable power generation.

Conclusion

In conclusion, energy containers are integral components of commercial and industrial energy storage systems, providing housing, protection, and essential functionalities for reliable and efficient operation. Understanding the various types of containers, their features, and components is essential for deploying robust and effective ESS solutions tailored to specific application needs.

Get In Touch

Recent Posts

-

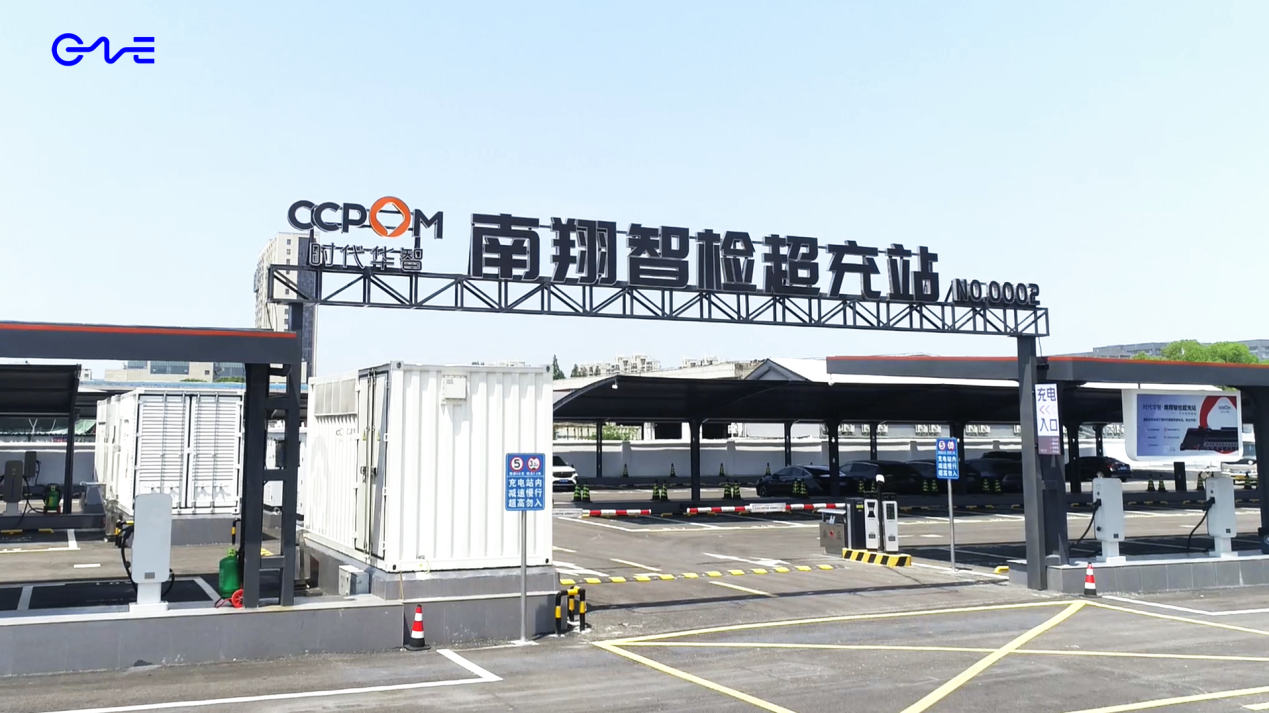

CNTE’s 90th Smart BESS EV Charging Station in operation in Shanghai

Jul 15, 2024 -

CNTE New Smart BESS EV Charging Station Landed in Shanghai

Jul 10, 2024 -

CNTE strategic signing at SNEC 2024 Shanghai

Jul 10, 2024 -

BP Group Co-operation Visit to CNTE

Jul 10, 2024 -

CNTE C&I ESS lands in Czech Industrial Park

Jul 10, 2024