Core Advantage – R&D Strength

System Integration

Possess technical competence insystem integration of the first smartBESS charging station in China

Team with 50% R&D expertise

Software & Hardware System

Professional experience in structural design

Awarded the title of IoT Enterprise

Module Design

Design and manufacture of PACK

10 overseas experts

Structural Design

Professional experience in structural design

Establishment of School-Enterprise

cooperation

Production Strength

The error-proof technology of the electromechanical design of the production line and the real-time collection and verification technology of the process parameters of the MES system ensure the manufacturing quality from both hardware and software, making the product qualification rate greater than 99.6%. (the industry average is cur- rently around 95%)

Lean logistics and lean production line layout, resulting in a 40% increase in the over- all efficiency of the manufacturing process.

The EMS system implements a dynamic collection of production data and production reports, and the ERP system dynamically adjusts logisticssupply and delivery according to customer demand. The production linecan reduce the overall operating costs by about 12% through achieving ademand-driven production flow.

The data docking and sharing between MES system and ERP andPLM systems have increased the design and manufacturing cycleof customized products for customers by 30%.

120000 ㎡Area of Plant

12 GWh Total Production

307 SetsNumber of Equipment

Near Industry 4.0 Technology

99.95%

Ultimate Qualification Rate

The implementation of error-proofing techniques in the electromechanical design of the production line, along with real-time collection and verification technology for process parameters through the MES system, guarantee superior manufacturing quality in both hardware and software aspects. This results in an exceptional production qualification rate of over 99.6%, surpassing the industry’s average rate of approximately 95%.

12%

Reduction Amplitude of Cost

The EMS system incorporates dynamic data collection and production reporting, while the ERP system dynamically adjusts logistics supply and delivery based on customer demand. This implementation of a demand-driven production process results in a notable reduction of approximately 12% in overall operating costs for the production line.

40%

Improvement in efficiency

The implementation of lean logistics practices and an optimized production line layout facilitate a remarkable 40% boost in the overall efficiency of the manufacturing process.

30%

Reduction in Cycle Time

The seamless data integration and sharing between the MES system, ERP, and PLM systems lead to a significant 30% improvement in the design and manufacturing cycle of customized products for customers.

Cell Strengths

Equipped with CATL LFP Cells

Electrical Safety

- Over-current / external short-circuit protection

- Insulation monitoring

- Equipontential bonding

- Electric shock warning

Mechanical Safety

- Vibration resistance

- Impact resistance

- Explosion-proof

Chemical Safety

- Flameresistant material

- Safety requirements of the battery cell

- Identification of hazardous substances

- Prevent Battery Thermal Runaway

Functional Protection

- Overvoltage / undervoltage protection

- Overtemperature/ low temperature protection

- Overcurrent protection

- Communication abnormal protection

Cell Process

Electrode sheet winding process is not easy to produce burr, decarbonization and Metal particle, low long-term cycle short circuit risk.

Safety Features

The results of the safety test: no fire, no explosion lithium iron phosphate has high thermal stability, slow heat production rate and less heat production lithium iron phosphate does not release oxygen under overcharge and overdischarge.

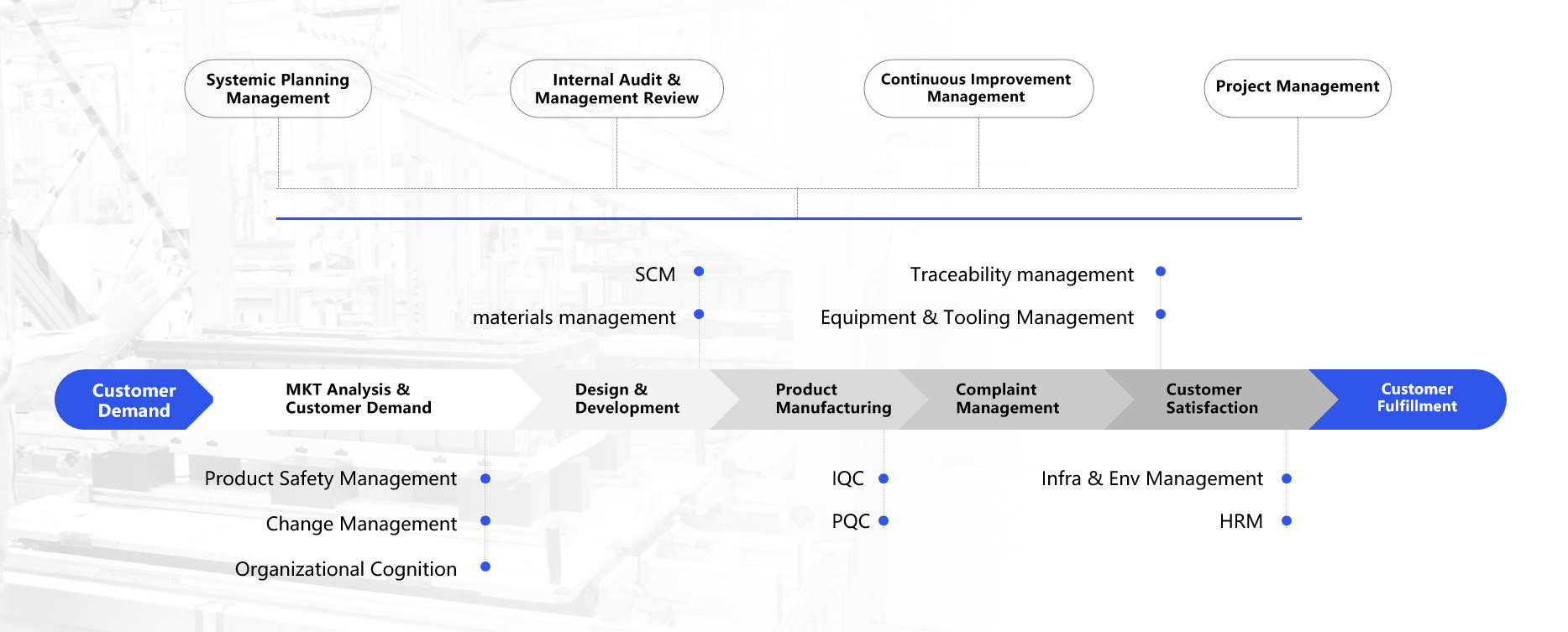

Customized Process and Management System

Strong R&D strength

Build scientific and technological hard power through 5 core technology matrices

CNTE’s core technology can promote the comprehensive application of lithium battery energy storage, which enables our company to provide all-scenario solutions for different customers. It enhances customer stickiness and expand market coverage accordingly.

Battery Testing Technology

The world’s first battery testing technology solution

The detection of parameters such as DCR and capacity retention rate of the power battery system can be completed during the charging process

High fault identification rate and fast speed

Battery Testing Technology

Leading electronic technology

Continuous optimization of electronic power technology now it has reached 1000V/360kW high-power DC charging and discharging system

Consistently meet needs of various product

Intelligent data technology

Industry-leading intelligent data technology

All products have realized cloud data tracking, and implemented AI algorithms gradually in aspects such as multiple analysis dimensions

Industry-leading digitization and intelligence

Battery integration technology

Battery integration core patent technology

Focus on the safety design of energy storage systems in key technical fields such as grouping, thermal management, fire protection, etc.

Integrated system with high security

Energy Management Technology

Based on the AI algorithm, the energy managementfunctions of energy storage such as peak shaving and valley filling, PV forecasting, and load forecasting can be realized

Accuracy, real-time, and interactivity are at the fore front of the industry

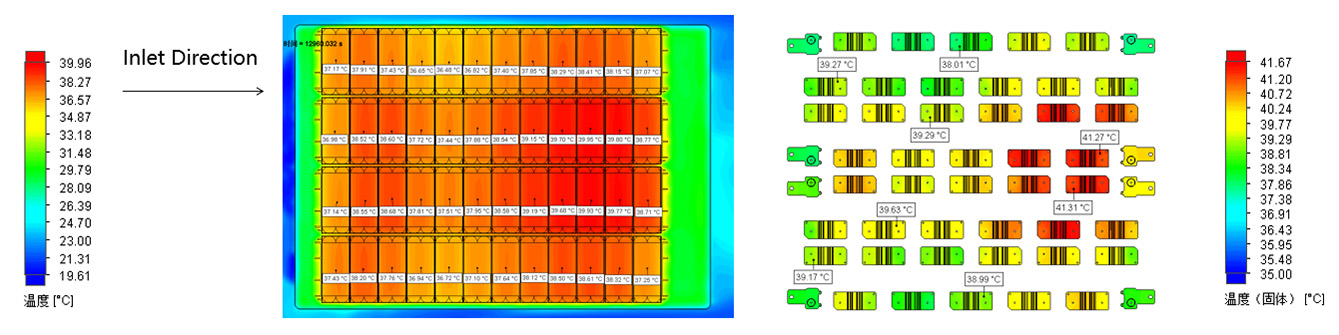

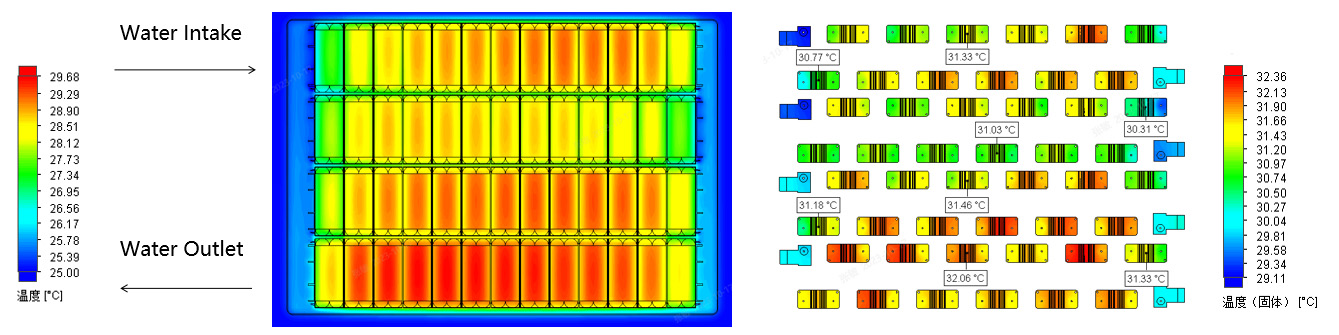

Thermal Management

Thermal simulation of air-cooled battery modules

Thermal Simulation of Liquid Cooled Battery Modules

Hornors

30+

Awards and Honours

MUSE Design Awards 2022 Gold Winner for YOSHOPO Residential ESS system

Fujian Provincial Enterprise Technology Center

The “Future Unicorn”Innovative Enterprise in the Digital Economy Field of Fujian Province

The National High-tech Enterprise

The Smart BESS Charging Station was recognized as the first set of Major Technical Equipment in Fujian Province

“Benchmark Product Award”of the National Advanced Energy Storage Technology Innovation Challenge

The “Gazelle” Innovative Enterprises iin the Digital Economy Field of Fujian Province

…………

579

Accumulated patent applications

194

Accumulated innovative patents

Certification

3 Systems Certification

ISO9001: 2015/GB/T19001-2016 The Quality Management System Requirements

ISO14001: 2015/GB/T24001-2016 The Environmental Management System Requirements

ISO45001: 2018/GB/T45001-2020 The OHS Management System Requirements

153 International Certification

1 Energy Storage Institute

300+ Experienced R&DExperts

25% R&DExpenses