Which Industries Are Harnessing the Power of High Voltage Inverters, and How?

Explore the forefront of high voltage power inverter technology, encompassing innovative advancements, safety standards, and upcoming trends. Delve into practical applications and uncover CNTE’s state-of-the-art solutions, driving efficient energy conversion and sustainable power electronics.

Introduction to High Voltage Power Inverters

1.1 Understanding High Voltage Power Inverters

High voltage power inverters serve as essential components in various applications across industries, enabling the conversion of DC (direct current) electricity into AC (alternating current) electricity. These devices are pivotal in scenarios where the power source generates DC electricity, but the load or application requires AC power. The significance of high voltage power inverters lies in their ability to facilitate seamless power conversion, thereby enabling the operation of numerous electronic devices, machinery, and systems.

1.2 Working Principles of Power Inverters

At the core of high voltage power inverters lies a fundamental principle of electrical engineering – the conversion between DC and AC power. Power inverters achieve this transformation through the use of electronic circuits, typically employing switches such as MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) or IGBTs (Insulated Gate Bipolar Transistors). These switches alternate to create an oscillating output waveform that mimics the characteristics of AC power, allowing compatibility with AC-driven devices.

1.3 Types of High Voltage Power Inverters

High voltage power inverters come in various types, each tailored to specific applications and requirements. Among the commonly encountered types are:

a. Pure Sine Wave Inverters: Produce a smooth and consistent AC waveform, suitable for sensitive electronics and appliances.

b. Modified Sine Wave Inverters: Generate an AC waveform with a modified square or stepped pattern, suitable for many applications but potentially causing issues with certain devices.

c. Grid-Tie Inverters: Interface renewable energy systems like solar panels or wind turbines with the utility grid, enabling the injection of excess power into the grid.

d. Off-Grid Inverters: Power standalone systems such as remote cabins or off-grid homes, are often integrated with batteries for energy storage.

Applications of High Voltage Power Inverters

2.1 Renewable Energy Systems

In the realm of renewable energy, high voltage power inverters play a crucial role in converting the DC output from solar panels or wind turbines into AC electricity suitable for grid integration or local consumption. These inverters ensure efficient utilization of renewable resources, contributing to the global shift towards clean energy.

2.2 Electric Vehicles

The automotive industry heavily relies on high voltage power inverters to propel the electrification revolution. In electric vehicles (EVs), inverters are integral to converting the DC power stored in the battery into AC power to drive the electric motor. The efficiency and performance of these inverters directly impact the range and acceleration of EVs, making them a critical component in the advancement of sustainable transportation.

2.3 Industrial Machinery

Industrial applications often demand high voltage power inverters to drive machinery and equipment efficiently. From variable frequency drives (VFDs) in manufacturing plants to motor control in heavy machinery, inverters enable precise speed and torque control, enhancing productivity and energy efficiency in industrial operations.

Design Considerations for High Voltage Power Inverters

3.1 Efficiency, Reliability, and Safety

When designing high voltage power inverters, engineers must prioritize efficiency, reliability, and safety. High efficiency ensures minimal energy loss during the conversion process, maximizing the utilization of available power sources. Reliability is paramount, especially in critical applications where downtime can result in significant losses. Additionally, stringent safety measures are essential to mitigate risks associated with high voltage operations, safeguarding both personnel and equipment.

3.2 Key Components and Design Challenges

Semiconductors, capacitors, transformers, and cooling systems are among the key components that influence the design and performance of high voltage power inverters. Selecting the appropriate components and optimizing their configurations are critical steps in achieving the desired efficiency and reliability. Design challenges such as thermal management, electromagnetic interference (EMI), and voltage transients require careful consideration and innovative solutions to ensure optimal operation and longevity of the inverters.

3.3 Optimizing Performance

To meet the diverse requirements of various applications, engineers employ advanced design techniques such as pulse width modulation (PWM), multilevel topology, and advanced control algorithms. These techniques enable the optimization of performance parameters such as output waveform quality, power density, and response time, enhancing the overall effectiveness of high voltage power inverters in their respective applications.

High Voltage Power Inverter Technologies

4.1 Exploring Advanced Technologies

In recent years, the landscape of high voltage power inverters has witnessed significant advancements driven by innovative technologies. One prominent trend is the adoption of wide bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN). These materials offer superior performance characteristics compared to traditional silicon-based semiconductors, including higher efficiency, faster switching speeds, and increased power density. Wide bandgap semiconductors enable the design of more compact and efficient inverters, contributing to enhanced energy conversion and system reliability.

4.2 Multi-Level Topologies and Digital Control Techniques

Another trend shaping the evolution of high voltage power inverters is the proliferation of multi-level topologies and digital control techniques. Multi-level inverters employ multiple voltage levels to achieve higher output waveform quality and reduced harmonic distortion, enhancing compatibility with sensitive loads and grid integration. Digital control techniques, such as pulse width modulation (PWM) and advanced algorithms, enable precise regulation of output voltage and frequency, facilitating optimal performance and response in various operating conditions.

4.3 Case Studies of Real-World Applications

Real-world applications provide tangible examples of how advanced technologies are leveraged to address specific challenges and requirements. Case studies showcasing the implementation of high voltage power inverters in fields such as renewable energy, electric transportation, and industrial automation demonstrate the practical benefits of innovative solutions. From grid-connected solar inverters utilizing wide bandgap semiconductors to electric vehicle inverters employing multi-level topologies, these examples illustrate the transformative impact of technology on modern power electronics.

Safety and Regulations in High Voltage Power Inverters

5.1 Importance of Safety Standards

Safety is paramount in the design and operation of high voltage power inverters to protect personnel, equipment, and the surrounding environment from potential hazards. Adherence to established safety standards and regulations is essential to ensure the reliability and integrity of inverters throughout their lifecycle. Standards such as IEC 61800-5-1 for adjustable speed electrical power drive systems and UL 1741 for grid-connected inverters outline specific requirements for performance, construction, and testing, guiding manufacturers and users in maintaining safety and compliance.

5.2 Overview of Compliance Requirements

Compliance with safety standards involves comprehensive testing and certification processes to validate the performance and reliability of high voltage power inverters. Manufacturers must demonstrate compliance with regulatory requirements related to electrical insulation, thermal management, overcurrent protection, and fault tolerance. Rigorous testing protocols assess the withstand capability of inverters under various operating conditions, ensuring robustness and resilience against potential faults or failures.

5.3 Best Practices for Ensuring Safety

Implementing best practices is essential for ensuring the safety of personnel and equipment when working with high voltage power inverters. Proper installation, maintenance, and operation procedures should be followed according to manufacturer guidelines and industry standards. Adequate training and certification programs empower personnel to handle inverters safely and respond effectively to emergencies. Additionally, ongoing monitoring and periodic inspections help identify potential risks and mitigate them proactively, enhancing overall safety and reliability.

Future Outlook of High Voltage Power Inverters

6.1 Predictions and Trends

The future development of high voltage power inverters is poised for continued innovation and advancement, driven by emerging technologies and evolving market demands. Predictions indicate a growing emphasis on efficiency, integration, and sustainability in inverter design and implementation. Trends such as the integration of energy storage systems, dynamic grid support capabilities, and smart grid integration are expected to shape the next generation of high voltage power inverters, enabling enhanced performance, flexibility, and resilience in power systems.

6.2 Emerging Technologies and Innovation

Emerging technologies hold immense potential for unlocking new capabilities and functionalities in high voltage power inverters. Innovations in materials science, device technology, and system architecture promise to further improve efficiency, reliability, and compactness. For instance, developments in advanced cooling techniques, advanced packaging technologies, and fault-tolerant designs aim to address thermal management challenges and enhance system robustness. Additionally, the integration of digital twins, artificial intelligence, and predictive analytics offers opportunities for proactive monitoring, diagnostics, and optimization of inverter performance in real time.

6.3 Considerations for Environmental Impact and Sustainability

As the importance of environmental sustainability grows, high voltage power inverters are expected to evolve towards greener and more eco-friendly solutions. Strategies for reducing energy losses, minimizing resource consumption, and mitigating environmental impact are becoming integral aspects of inverter design and operation. Integration with renewable energy sources, energy storage systems, and demand response programs enables high voltage power inverters to contribute to a more sustainable and resilient energy infrastructure. Moreover, advancements in recyclability, lifecycle assessment, and eco-design principles promote the development of environmentally responsible inverters that align with global sustainability goals.

Conclusion

In conclusion, high voltage power inverters manufactured by CNTE and similar companies serve as indispensable components across a wide spectrum of industries and applications. From renewable energy systems to electric vehicles and industrial machinery, these inverters enable the efficient conversion of DC power into AC power, driving innovation and sustainability in modern technology. With continuous advancements in design and technology, high voltage power inverters are poised to play an increasingly pivotal role in shaping the future of energy and transportation.

Get In Touch

Recent Posts

-

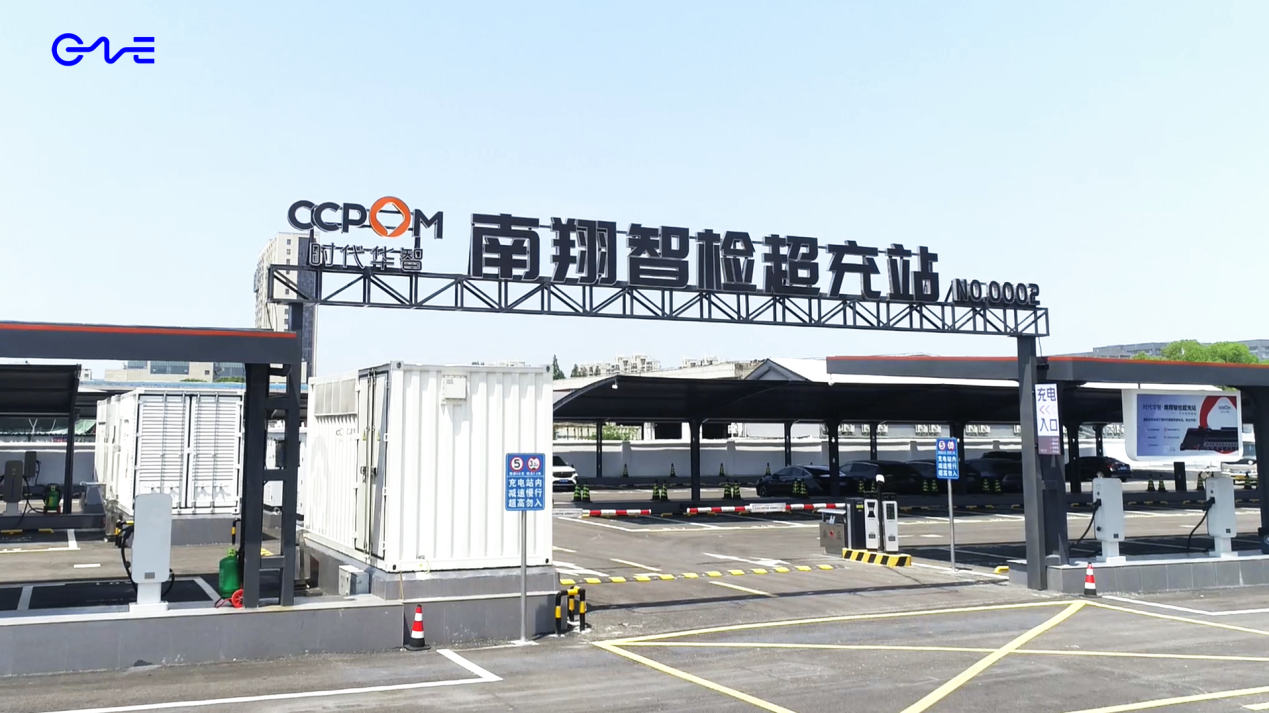

CNTE’s 90th Smart BESS EV Charging Station in operation in Shanghai

Jul 15, 2024 -

CNTE New Smart BESS EV Charging Station Landed in Shanghai

Jul 10, 2024 -

CNTE strategic signing at SNEC 2024 Shanghai

Jul 10, 2024 -

BP Group Co-operation Visit to CNTE

Jul 10, 2024 -

CNTE C&I ESS lands in Czech Industrial Park

Jul 10, 2024