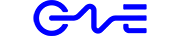

Smart BESS Charging & Testing Station

Lorem ipsum dolor sit amet, inciderint referrentur te vim.

The intelligent microgrid system is formed under the control of the EMS, combined with renewable energy access, ESS, EV charging and testing service.

Home >

Product Advantages

Reducing light energy waste

Reducing light energy waste, improving the utilization rate of clean energy

Super Fast Charging

Recharge to 80% in as little as 10 minutes

Battery Detection

Provide battery testing service while charging

Fast Construction

Modular design, flexible deployment, shortened construction period

DC Bus Architecture

Isolate the impact of charging load disturbance on the grid

Emergency Power Backup

Isolated island operation, switching between parallel and off gird to ensure stable charging

High Security

Liquid cooling system, perfluorohexanone electric box fire protection

Increase Revenue

Peak-valley arbitrage, compound benefits of multiple forms of business

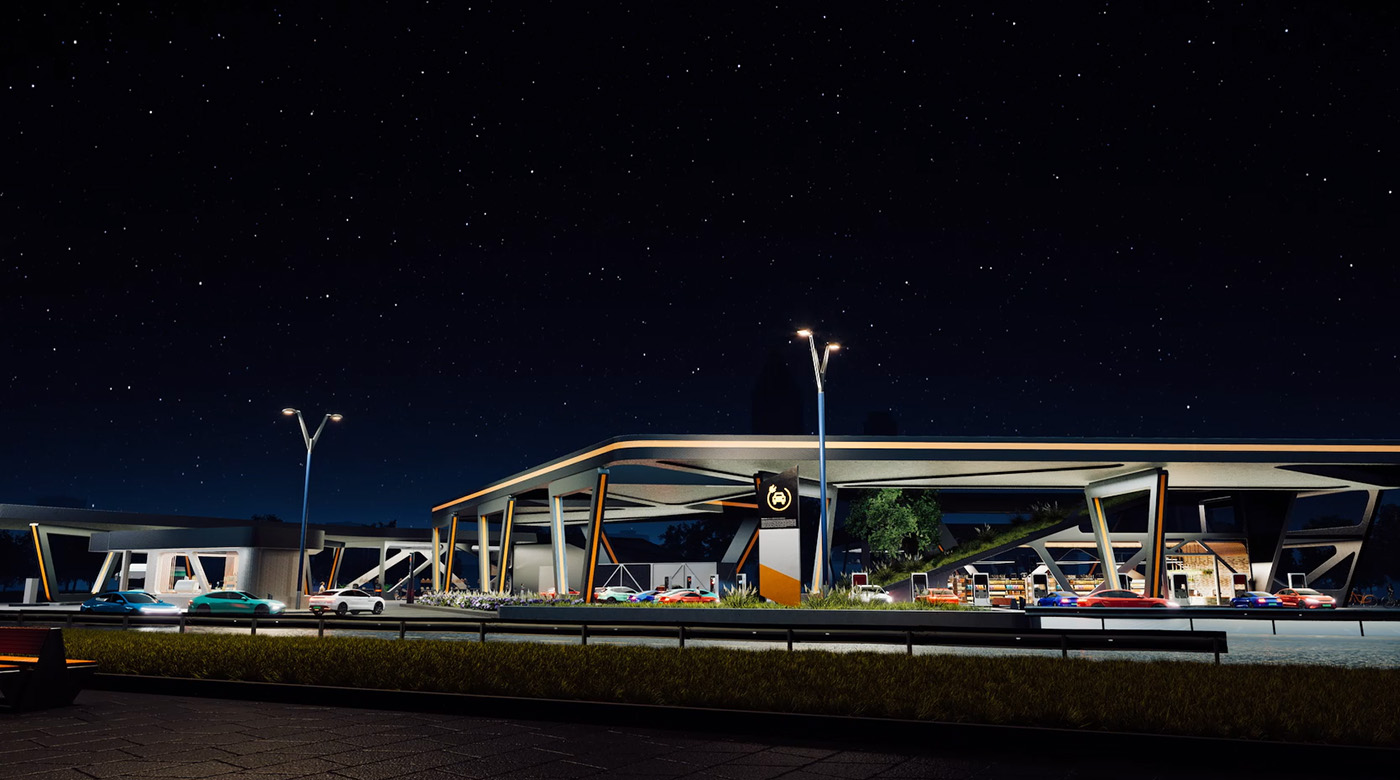

Application Scenario

View All

Expressway Service Area

Community Charging Station

Airport

Parking Lot

Bus Station

Taxi Stand

Supporting Products

Smart BESS Container

Charging Piles

EMS/Monitoring Centre

The Smart Remote Management Application

-

Liquid Cooling Smart BESS Container

| Max. number of charging piles in parallel | 24 |

| INVERTER SPECIFICATIONS | |

| Rated AC Power | 500kW |

| Rated Grid Voltage | 400 Vac |

| Frequency | 50/60Hz |

| Peak Efficiency | 98.3% |

| ENVIRONMENTAL | |

| Operating Temperature Range / Humidity Range | -20~50 °C (Inverter derating at 45 to 55 °C) / 0 to 95% RH non-condensing |

| Altitudes | <4000m (derating >2000m) |

| IP Ratings | Energy Storage IP54, PCS IP54, Control Cabinet IP54 |

| DIMENSIONS & WEIGHTS OF KEY COMPONENTS | |

| System Dimensions (mm, L x W x H) | 1295 X 1500 X 2280 for each Battery Rack 1200 x 800 x 2000 for Control Cabinet |

| Weight of Key Components (kg) | 1000 kg for Control Cabinet, 2500 kg per 206 kWh Battery Rack |

| ENERGY STORAGE | |

| Max Energy DC | 1030kWh |

| Voltage Range (Nominal Voltage) | 646.8 ~ 831.6VDC ( 739.2VDC ) |

| Chemistry | LFP |

| CHARGING PILE | |

| Max. Output Power | 180kW |

| Output Voltage Range | 200~1000Vdc |

| FEATURES | |

| Battery Monitoring System | YES ‒ Capable through CNTE monitoring system |

| Fire Suppression System | Pre-integrated Fire Suppression System with smoke and heat detectors plus aerosols or NVAC1230 |

| COMPLIANCE | |

| Inverter Related Standards | IEC 62477, IEC 61000-6-2, IEC 61000-6-4, EN 50549, G99, AS/NZS 4777.2:2020, NRS 097-2-1:2017 |

| Battery Related Standards | UN 38.3, UN 3481, IEC 62619, IEC 61000-6-2/-4, IEC 62477-1 |

-

Liquid Cooling Smart BESS Container

| Max. number of charging piles in parallel | 24 |

| INVERTER SPECIFICATIONS | |

| Rated AC Power | 500kW |

| Rated Grid Voltage | 400 Vac |

| Frequency | 50/60Hz |

| Peak Efficiency | 98.3% |

| ENVIRONMENTAL | |

| Operating Temperature Range / Humidity Range | -20~50 °C (Inverter derating at 45 to 55 °C) / 0 to 95% RH non-condensing |

| Altitudes | <4000m (derating >2000m) |

| IP Ratings | Energy Storage IP54, PCS IP54, Control Cabinet IP54 |

| DIMENSIONS & WEIGHTS OF KEY COMPONENTS | |

| System Dimensions (mm, L x W x H) | 1295 X 1500 X 2280 for each Battery Rack 1200 x 800 x 2000 for Control Cabinet |

| Weight of Key Components (kg) | 1000 kg for Control Cabinet, 2500 kg per 206 kWh Battery Rack |

| ENERGY STORAGE | |

| Max Energy DC | 1030kWh |

| Voltage Range (Nominal Voltage) | 646.8 ~ 831.6VDC ( 739.2VDC ) |

| Chemistry | LFP |

| CHARGING PILE | |

| Max. Output Power | 180kW |

| Output Voltage Range | 200~1000Vdc |

| FEATURES | |

| Battery Monitoring System | YES ‒ Capable through CNTE monitoring system |

| Fire Suppression System | Pre-integrated Fire Suppression System with smoke and heat detectors plus aerosols or NVAC1230 |

| COMPLIANCE | |

| Inverter Related Standards | IEC 62477, IEC 61000-6-2, IEC 61000-6-4, EN 50549, G99, AS/NZS 4777.2:2020, NRS 097-2-1:2017 |

| Battery Related Standards | UN 38.3, UN 3481, IEC 62619, IEC 61000-6-2/-4, IEC 62477-1 |

-

Liquid Cooling Smart BESS Container

| Max. number of charging piles in parallel | 24 |

| INVERTER SPECIFICATIONS | |

| Rated AC Power | 500kW |

| Rated Grid Voltage | 400 Vac |

| Frequency | 50/60Hz |

| Peak Efficiency | 98.3% |

| ENVIRONMENTAL | |

| Operating Temperature Range / Humidity Range | -20~50 °C (Inverter derating at 45 to 55 °C) / 0 to 95% RH non-condensing |

| Altitudes | <4000m (derating >2000m) |

| IP Ratings | Energy Storage IP54, PCS IP54, Control and DC Combiner Cabinet IP54 |

| DIMENSIONS & WEIGHTS OF KEY COMPONENTS | |

| System Dimensions (mm, L x W x H) | 1295 X 1500 X 2280 for each Battery Rack 1200 x 800 x 2000 for Control Cabinet |

| Weight of Key Components (kg) | 700 kg for Control Cabinet, 2500 kg per 206 kWh Battery Rack |

| ENERGY STORAGE | |

| Max Energy DC | 1030kWh |

| Voltage Range (Nominal Voltage) | 646.8 ~ 831.6VDC ( 739.2VDC ) |

| Chemistry | LFP |

| CHARGING PILE | |

| Max. Output Power | 180kW |

| Output Voltage Range | 200~1000Vdc |

| FEATURES | |

| Battery Monitoring System | YES ‒ Capable through CNTE monitoring system |

| Fire Suppression System | Pre-integrated Fire Suppression System with smoke and heat detectors plus aerosols or NVAC1230 |

| COMPLIANCE | |

| Inverter Related Standards | UL 1741, UL 1741 SB, IEEE 1547:2018 |

| Battery Related Standards | UN 38.3, UN 3481, UL 1973, UL 9540A |